Tel : +8613405103650 Email : sales4@likaymo.com

What Are You Looking For

What Are You Looking For

Tel : +8613405103650 Email : sales4@likaymo.com

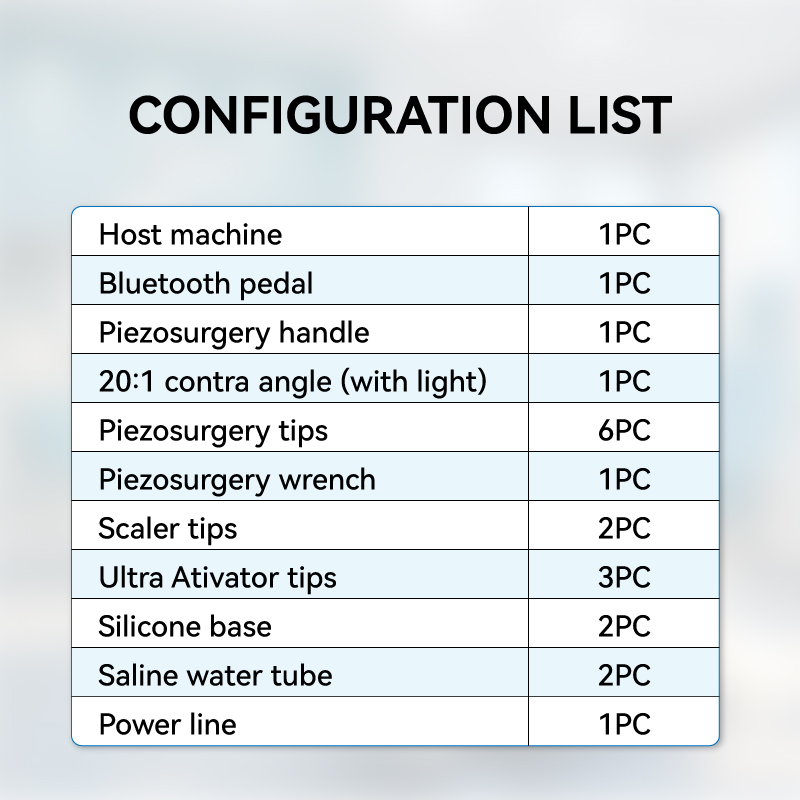

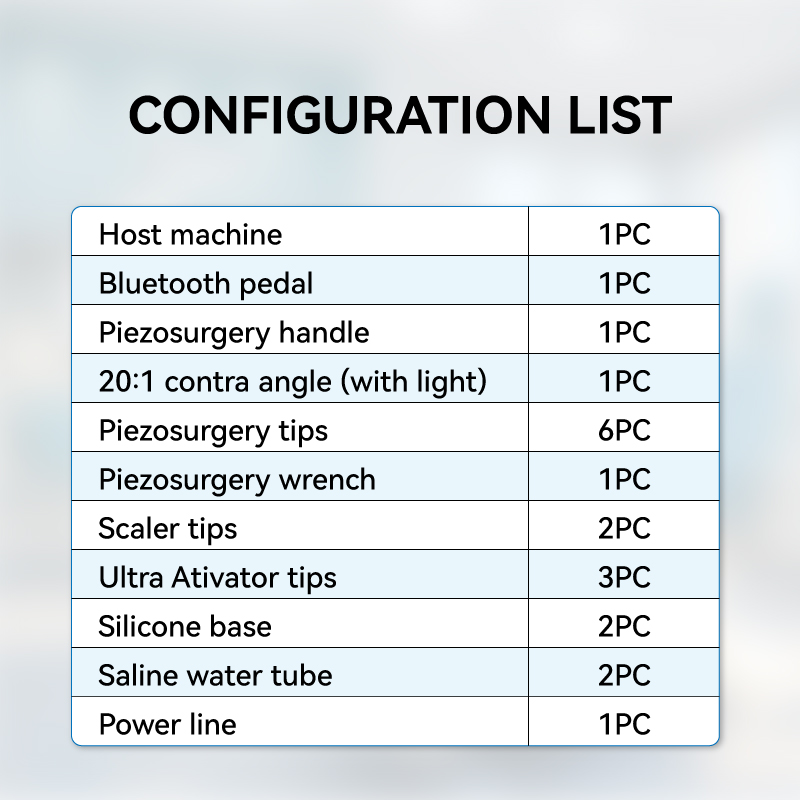

4-in-1 dental system integrates implants, bone surgery, scaling & endo activation. Features 55N.cm torque, 2000 RPM speed, real-time display, and forward/reverse rotation. Complete with implant handpiece, surgery tools, and accessories—an all-in-one professional solution for modern clinics.

Model Type :

J100Base Size :

48*48cm/18.9*18.9 inchesColumn Material :

Aircraft-grade aluminumVesa :

75x75/100x100mmLaptop size :

15-32"Email : sales4@likaymo.com

4-in-1 Dental Implant & Surgery Machine

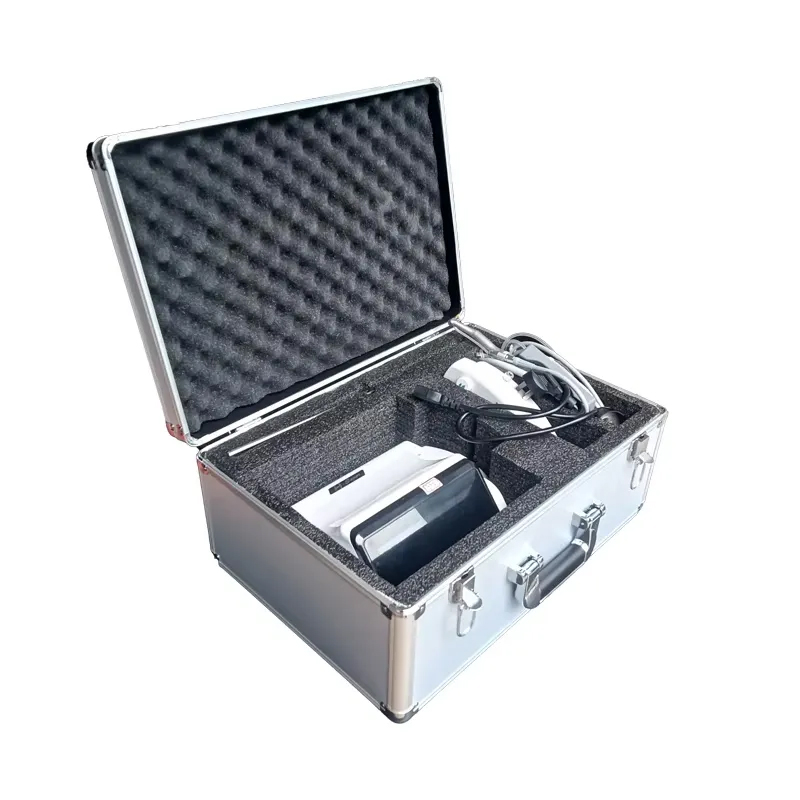

The J100 is a professional all-in-one dental implant and surgical system. Built with durable metal components, it is compact (packaged in a 48*33*21cm box, 6.34kg) and integrates seamlessly into clinics. Manufactured under the Likaymo brand in China, it meets international standards and supports implants, bone surgery, scaling, and endo activation in one efficient device.

This unit is a versatile dental implant and bone surgery machine that integrates multiple functions into one professional system. It is designed to accommodate a wide range of procedures through its modular handpiece system, including US1–US5 ultrasonic scalers, UC1 and UL3 endo/periodontal tips, and surgical attachments.

Key to its performance are the three specialized handpieces:

A 1:1 low-speed handpiece for bone grafting, trimming, and surgical drilling A 1:5 increasing handpiece for efficient osteotomy preparation

A 20:1 reduction implant handpiece powered by an electric motor, delivering high torque for precise and stable implant placement

With support for modules labeled B20/02, G20/02, C20/02 and compatibility with G1 and P1 attachments, this system offers a complete, all-in-one solution for implantology, oral surgery, and supportive dental therapies.

Implant Machine — Complete Handpiece System for Every Procedure

This professional implant machine is engineered to deliver full surgical versatility through its integrated handpiece system. It includes three specialized attachments to cover the entire workflow:

1:1 low-speed handpiece – Ideal for bone grafting, trimming, and precision surgical tasks

1:5 increasing handpiece – Enables efficient, high-speed drilling for osteotomy preparation

20:1 implant handpiece – Powered by an electric motor, it delivers high torque and controlled low speed for stable, accurate implant placement

Together, these handpieces form a complete all-in-one system, allowing clinicians to perform implants, bone surgery, and related procedures seamlessly with a single device.

Manufacturing, Processing, Packing & Loading

FAQS

Q1: Are you a manufacturer or trading company?

A: We are a certified manufacturer with in-house capabilities including product design, surface treatment (painting), and full assembly services.

Q2: Can your products be customized to fit our specific requirements?

A: Absolutely. As a manufacturer, we specialize in providing tailored solutions, including dimensional adjustments, interface compatibility, and functional modifications to meet unique application needs.

Q3: What are your standard lead times?

A: Within 50 units: 1 week

100 units and above: 10 working days

200 units and above: 15 working days

Customized solutions may require additional time, which will be communicated in advance

Q4: What is your MOQ and can you support small-batch trial orders?

A: Our standard MOQ is 1 unit for evaluation purposes. We actively encourage and support small-batch trial orders to help clients verify product quality and compatibility before full commitment.

Q5: How do you ensure quality control during production?

A: We implement a strict IQC/IPQC/OQC system with full-process inspections. Key components are traceable, and each critical production stage must pass our quality gate checks.

Q6: What certifications do your products and company hold?

A: We are ISO 9001:2015 certified. Our products also comply with international safety and EMC standards, holding CE certification. Other certifications can be discussed based on market requirements.

Q7: Do you provide pre-order samples? What's the availability?

A: Yes, we provide evaluation samples for quality verification.Processed within 3-5 business days for all sample requests. Available for both stocked and made-to-order items

Q8: How do you handle defective products?

A: We offer a 12-month warranty with replacement/refund for manufacturing defects, supported by our traceability system.

Q9: What are your payment terms?

A: Standard terms are 50% deposit with order, 50% balance before shipment. For long-term partners, we offer more flexible arrangements.

Q10: Which ports do you ship from?

A: Primarily Shanghai/Ningbo ports with optional air freight from Shanghai Pudong Airport.

Q11: Do you provide installation guides or maintenance training?

A: We supply detailed manuals with QR video guides, plus optional remote assistance

Q12: Do you provide spare parts and long-term technical support?

A: Yes, we guarantee a 5-year supply of core spare parts. Our technical support team is available for remote assistance and lifetime consultation.

Q13: What's your company location?

A: Our manufacturing base is located in Haian City, Jiangsu Province, China - a key industrial hub in Eastern China.

Tags :

MT-1U.pdf

Leave A Message

Scan to WhatsApp :